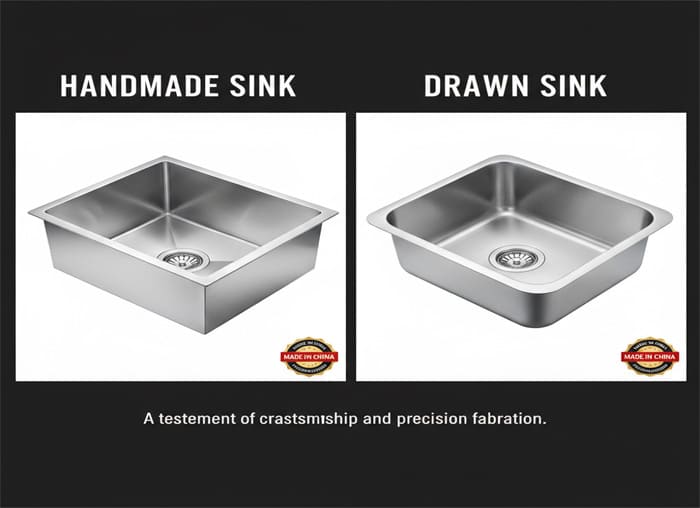

You’re standing in a kitchen showroom, looking at two stainless steel sinks that seem similar at first glance. One has sharp, crisp corners and a commanding presence. The other has softer, rounded edges and a seamless look. The price tags are noticeably different. You’re looking at the fundamental choice in the world of stainless steel sinks: Handmade vs. Drawn.

Making the right choice is about more than just looks; it’s about understanding how a sink is born. This decision impacts your kitchen’s style, functionality, and budget. This guide will demystify the entire process, empowering you to choose with the confidence of an industry pro.

Last Updated: Nov 2025 | Estimated Reading Time: 19 minutes

What Exactly is a Handmade Sink? The Art of Fabrication

A handmade sink is a testament to craftsmanship and precision fabrication. Despite its name, it involves sophisticated machinery guided by skilled artisans. It is a more traditional method, but one that has been perfected for the modern luxury market.

The process is one of construction:

- Cutting: A flat sheet of heavy-gauge stainless steel (typically 16 to 18 gauge) is precisely cut by laser.

- Bending: The sheet is bent on a machine press brake to form the straight side walls of the sink.

- Welding: The corners are then meticulously welded together. This is the most critical step. High-end manufacturers use advanced welding techniques, and the seams are then ground and polished to become virtually invisible.

- Finishing: The entire sink is then hand-polished and finished to create a uniform, often luxurious, brushed texture.

This method results in a sink with distinct, sharp corners (often called “zero radius” or “near-zero radius”) and perfectly straight, flat sides.

Expert Insight: You noted that handmade sinks have lower market acceptance due to high cost. While historically true, this has shifted dramatically. The trend towards modern, architectural kitchens has made handmade sinks the aspirational standard in the mid-to-high-end market. Their “high-end” perception is now a major selling point.

What Exactly is a Drawn Sink? The Power of Industrial Pressing

A drawn sink (also known as a pressed sink) is a marvel of modern industrial efficiency. It is, as you correctly noted, an evolution in manufacturing that allows for mass production and lower costs.

The process is one of formation:

- Stamping: A single, thinner sheet of stainless steel (typically 18 to 22 gauge) is placed over a die (a mold of the sink).

- Pressing: A massive hydraulic press pushes the steel sheet down into the die, stretching and forming it into the shape of the sink in a single, powerful motion.

- Finishing: The excess steel is trimmed, drain holes are punched, and the sink is polished.

Because the steel is stretched, the corners and bottom of the sink are inherently rounded and sloped. The metal is also slightly thinner at the corners and bottom than at the top flange due to this stretching process.

Head-to-Head: The Ultimate Handmade vs. Drawn Sink Comparison

This table breaks down the fundamental differences to help you understand the trade-offs at a glance.

| Feature | Handmade Sink | Drawn Sink | What This Means For You |

|---|---|---|---|

| Manufacturing | Cut, bent, and welded from a steel sheet. | Stamped and stretched from a single sheet. | Handmade is artisan-led fabrication; Drawn is industrial mass production. |

| Aesthetics | Sharp, crisp corners (0-15mm radius). Architectural and modern look. | Soft, rounded corners (25mm+ radius). Traditional and transitional look. | Your kitchen’s entire style can be defined by this choice. |

| Steel Gauge | Typically thicker (16-18 gauge). | Typically thinner (18-22 gauge). | A thicker gauge means less noise (less “tinny”) and more dent resistance. |

| Bowl Space | Maximized. Straight walls mean 100% usable flat bottom space. | Slightly reduced. Sloped walls and curved corners take up volume. | Handmade sinks fit large pots and baking sheets more easily. |

| Cleaning | Corners can require more attention to prevent buildup. | Rounded corners are exceptionally easy to wipe clean. | This is a key lifestyle consideration. If you hate cleaning corners, drawn is your friend. |

| Cost | Higher due to more labor, thicker steel, and complex process. | Lower due to high efficiency, less labor, and less material. | Handmade is a premium investment; Drawn is the value-oriented choice. |

| Durability | Extremely durable due to thick gauge. Welds are a potential (but rare) point of failure on low-quality models. | Seamless body is incredibly strong. Thinner gauge can be more prone to dents. | Both are highly durable. Handmade’s thicker steel gives it a slight edge in dent resistance. |

| 2025 Market Trend | Dominant in mid-to-high-end and luxury custom kitchens. | The standard for budget-conscious projects, multi-family housing, and traditional kitchens. | The market is moving towards handmade for aspirational kitchen designs. |

Deep Dive: The Three Factors That TRULY Matter

Let’s go beyond the surface and explore the three most critical differences that will impact your daily life.

1. Aesthetics & Design: The Power of the Corner Radius

The single most visible difference is the corner radius. This number dictates the entire personality of your sink.

- Handmade Sinks (Zero to Small Radius):

- 0-10mm Radius: Often called “zero radius” or “near-zero radius.” This creates a sharp, geometric, and uncompromisingly modern look. It’s the top choice for architects and designers creating minimalist or industrial-style kitchens.

- 10-15mm Radius: Sometimes called “R10” or “R15.” This offers a “softened modern” look. You get the crisp aesthetic of a handmade sink, but the slightly curved corners are easier to clean. This is the fastest-growing segment in the premium market.

- Drawn Sinks (Large Radius):

- 25mm+ Radius: These deep, sweeping curves are a hallmark of the drawing process. They create a softer, more traditional look that blends seamlessly into classic or transitional kitchen designs. They are exceptionally practical and forgiving.

| Radius Type | Visual Style | Cleaning Ease | Best Kitchen Style |

|---|---|---|---|

| Zero Radius (0-10mm) | Ultra-Modern, Architectural | More effort required | Minimalist, Industrial, Contemporary |

| Small Radius (10-15mm) | Soft Modern, Professional | Moderate | Transitional, Modern Farmhouse |

| Large Radius (25mm+) | Traditional, Classic | Easiest | Classic, Country, Budget-Friendly |

2. Performance & Durability: Gauge and Sound

Steel Gauge: In the world of sheet metal, a lower number is thicker.

- 16 Gauge (1.5mm): The gold standard for high-end handmade sinks. It’s heavy, quiet, and extremely resistant to denting.

- 18 Gauge (1.2mm): A very common and respectable thickness for both quality drawn sinks and many handmade sinks. A great balance of durability and cost.

- 20-22 Gauge (0.9-0.8mm): Typically found on budget-friendly drawn sinks. It’s more prone to denting and can produce more noise from water and disposals (a “tinny” sound).

Pro Tip: Don’t just look at the gauge. Check the quality of the sound-dampening pads. Top-tier manufacturers (of both sink types) cover at least 80% of the sink’s exterior with thick rubber pads to absorb vibration and noise. This makes a huge difference.

3. Cost & Value: Where Your Money Goes

You were spot-on: efficiency drives the cost difference.

- Why Handmade is More Expensive:

- More Labor: The process of cutting, bending, welding, and hand-finishing is labor-intensive.

- More Material: They use thicker, more expensive sheets of steel.

- Less Waste, More Skill: While the process creates less scrap material, it requires highly skilled technicians, whose time is valuable.

- Why Drawn is More Affordable:

- Automation: The stamping process is incredibly fast and highly automated.

- Less Labor: Fewer man-hours are required per unit.

- Material Efficiency: While the process may create more scrap from the initial blank, the ability to use thinner gauge steel lowers the overall material cost.

The value proposition is clear: With drawn sinks, you pay for efficient production. With handmade sinks, you pay for thicker steel, maximized bowl space, and a premium aesthetic.

Which Sink is Right For YOU? A Decision-Making Guide

Answer these questions to find your perfect match.

You should choose a HANDMADE SINK if…

- Your Style is Modern: You have flat-panel cabinets, clean lines, and a minimalist or industrial aesthetic.

- You Need Maximum Space: You frequently wash large baking sheets, woks, or stockpots and need every square inch of a flat sink bottom.

- You Are a “Kitchen Enthusiast”: You see your sink as a high-performance workstation and are willing to invest in premium quality and design.

- You Don’t Mind the Upkeep: You are diligent about cleaning and will take a moment to wipe down the corners to keep them pristine.

You should choose a DRAWN SINK if…

- Your Style is Traditional or Transitional: You have shaker cabinets, detailed finishes, and a softer, more classic kitchen design.

- Easy Cleaning is Your #1 Priority: You want a low-maintenance sink that you can wipe clean in seconds.

- You Are Budget-Conscious: You want a durable, reliable sink that offers the best possible performance for the price.

- You’re Sourcing for a Rental or Flip: You need a universally appealing, bulletproof sink that will stand up to years of use with minimal fuss.

The Perfect Pairing: Matching a Faucet to Your Sink

A world-class sink deserves a world-class faucet. The faucet is the most interactive part of your kitchen workspace, and its quality and style are paramount. This is where a specialized faucet manufacturer can complete your vision.

SpringFaucet: The Ideal Faucet Partner for Your New Sink

- Founded: 2006

- Company Introduction: SpringFaucet is an ISO9001 certified enterprise that specializes in the design and production of sustainable, high-quality faucets. They are the perfect partner for pairing with the sinks from China’s top manufacturers, offering a level of style, quality, and flexibility that complements any choice.

- Core Strengths for Your Kitchen:

- Material Synergy: As experts in stainless steel faucets, they offer the perfect material match for the vast majority of high-quality Chinese sinks.

- Color Coordination: For the increasingly popular Nano-PVD sinks (black, gold, gunmetal), SpringFaucet offers a wide range of matching PVD faucet finishes, ensuring a seamless and high-design look. Consumers love this coordinated aesthetic.

- Flexibility for B2B: For importers or developers, SpringFaucet offers flexible MOQs (Minimum Order Quantity), allowing you to source the perfect faucet for your project or brand without massive volume commitments.

B2B Sourcing Tip: When sourcing sinks from a Chinese manufacturer for your brand, don’t rely on their default faucet offering. Partner with a dedicated faucet specialist like SpringFaucet. This allows you to create a superior “bundle” with a better-quality, better-designed faucet, giving your brand a significant competitive advantage.

Frequently Asked Questions (FAQ)

Q1: Are the welds on a handmade sink a weak point? On a high-quality handmade sink from a reputable manufacturer, no. They use advanced robotic or TIG welding and finishing processes that make the weld as strong as, or even stronger than, the parent metal. On a cheap, poorly made handmade sink, however, welds can be a potential point for rust or failure. Always buy from a trusted brand.

Q2: Are handmade sinks really harder to clean? They require more attention, but not necessarily more effort. A quick wipe with a cloth after use is usually sufficient. The “hard to clean” reputation comes from letting food particles dry and accumulate in the sharp 90-degree corners. A small-radius (R10/R15) handmade sink is the perfect compromise.

Q3: Do drawn sinks dent more easily? A thinner gauge drawn sink (22g) will dent more easily than a thick gauge handmade sink (16g). However, a quality 18-gauge drawn sink is still very robust and perfectly adequate for most residential kitchens. The seamless construction also means there are no welds to worry about.

Conclusion: The Artisan vs. The Industrial Powerhouse

The choice between a handmade and a drawn sink is a choice between two different philosophies.

The drawn sink is the triumph of industrial ingenuity. It delivers incredible durability, easy maintenance, and outstanding value through a highly efficient process. It is the undisputed, practical workhorse of the kitchen world.

The handmade sink is the expression of modern craftsmanship. It offers an architectural aesthetic, superior materials, and maximized utility for the discerning user. It is an investment in design and a statement piece that defines a high-end kitchen.

There is no single “better” sink—only the sink that is better for you. By understanding their origins, their strengths, and how they align with your style and needs, you can now choose the perfect stainless steel heart for your kitchen.

Recommended Links

Internal Links:

- A Guide to Stainless Steel Gauges for Kitchen Sinks

- Top China Kitchen Sink Manufacturers: A Sourcing Guide

- How to Choose the Perfect Faucet for Your Kitchen Sink

External Links (Authoritative Sources):

- Wikipedia: Deep Drawing – For a technical understanding of the manufacturing process behind drawn sinks.

- American Iron and Steel Institute (AISI) – An authoritative source on steel grades and properties, including the 304 stainless steel used in sinks.

- Architectural Digest: Kitchen Design Trends – To see how handmade sinks are used in high-end, modern kitchen designs by top architects.