If you’re looking to launch or expand a faucet brand, the terms OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) are the two most important acronyms you’ll encounter. Choosing the right path is the single most critical decision that will shape your brand’s identity, budget, speed-to-market, and long-term potential. This guide will demystify these two manufacturing models, providing you with a clear framework to decide which strategy is the perfect fit for your business goals.

Last Updated: Nov 2025 | Estimated Reading Time: 15 minutes

OEM vs. ODM: The Core Distinction at a Glance

Let’s start with the foundational difference. The key distinction lies in who owns the design and intellectual property (IP).

- OEM (Original Equipment Manufacturer): You Design, They Build. In an OEM partnership, you (the client) provide the manufacturer with a complete, detailed, and production-ready design. You own 100% of the intellectual property—the technical drawings, the unique aesthetic, the functional innovations. The manufacturer’s role is to use their equipment and expertise to execute your vision precisely.

- Analogy: You are the architect who hands a full set of blueprints to a construction company to build your custom dream home.

- ODM (Original Design Manufacturer): They Design, You Brand. In an ODM partnership, the manufacturer has already invested in designing and engineering a range of products. You select a product from their existing catalog and then customize it to fit your brand. Customizations can range from simple (adding your logo) to more complex (changing the handle, offering a unique PVD finish, or using a specific cartridge). The core design and engineering IP belong to the manufacturer.

- Analogy: You are buying a home in a new development. You can’t change the foundation or the floor plan, but you can choose the paint colors, flooring, and fixtures to make it your own.

| Feature | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Design Origin | The Client (You) | The Manufacturer |

| Intellectual Property | Owned by the Client | Owned by the Manufacturer |

| Upfront Investment | High (R&D, tooling, molds) | Low (No R&D or mold costs) |

| Time-to-Market | Slow (6-12+ months) | Fast (1-3 months) |

| Product Uniqueness | Completely Unique | Not Unique (Other brands can sell similar models) |

| Ideal For | Established brands, high-end niches | Startups, mass retailers, budget-conscious brands |

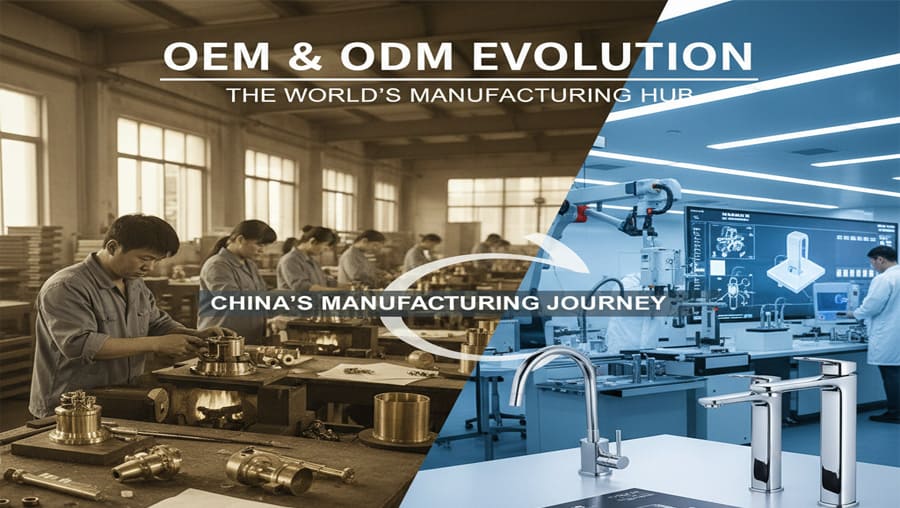

The Evolution of Faucet Manufacturing in China: From Copying to Creating

To truly understand OEM and ODM in the faucet industry, you have to understand its history in China—the world’s manufacturing hub. This evolution mirrors the journey of many successful Chinese factories.

Phase 1: The OEM Survival Era (1980s – 1990s)

The modern faucet’s journey started in Europe with German and Italian design and engineering. This technology and design aesthetic then migrated to Taiwan, which became a major production hub. From Taiwan, the knowledge and manufacturing base shifted to mainland China, primarily settling in Guangdong province.

In these early days, Chinese factories had limited design or R&D capabilities. Their path to survival and growth was pure OEM. Global giants like Hansgrohe, Kohler, and Moen would provide their designs, and the Chinese factories would serve as their manufacturing arms. The mission was simple: learn to produce products to world-class standards. This was a crucial period of learning—mastering brass casting, precision machining, and high-quality chrome plating. They weren’t designing; they were perfecting the art of making.

Phase 2: The ODM Growth Era (2000s – 2010s)

After decades of OEM manufacturing for the world’s best brands, these Chinese factories had accumulated immense technical expertise. They began to evolve. They started by making small modifications to existing designs for different clients, which was the birth of ODM.

They established their own small R&D teams and began creating their own product lines, heavily inspired by the European designs they had been producing. This allowed them to offer a catalog of pre-designed products to new clients who didn’t have the resources for full OEM. This ODM model fueled explosive growth, allowing smaller international brands to enter the market quickly.

Phase 3: The Innovation & Brand Power Era (2010s – Present)

Today, the landscape has completely transformed. Leading Chinese manufacturers, like Huayi in Guangdong or Jomoo in Fujian, are no longer just followers. They have invested heavily in state-of-the-art R&D centers, employing international designers and securing thousands of patents. They now drive innovation, creating original designs and technologies that they export globally under their own brands and through sophisticated ODM partnerships. They have completed the journey from pure OEM copiers to global design leaders.

Expert Tip: When evaluating a potential manufacturing partner, ask them about their company’s history. A factory that can articulate this journey from OEM to ODM demonstrates a deep understanding of the industry and a proven track record of growth and learning.

A Deep Dive into the OEM Process: The Path to a Unique Product

Choosing the OEM route is a significant undertaking, but it offers the ultimate reward: a product that is uniquely yours.

The Step-by-Step OEM Faucet Development Process:

- Concept & Design: You develop the initial idea, sketches, and detailed 3D CAD models.

- Technical Drawings: Your team creates precise engineering drawings with all specifications (dimensions, materials, tolerances).

- Manufacturer Selection: You vet and select a factory with the specific technical capabilities to produce your design.

- Tooling & Mold Creation: The factory creates new molds and tooling specifically for your product. This is the most expensive and time-consuming step.

- Prototyping & Sampling: The factory produces initial prototypes for you to test for form, fit, and function.

- Refinement & Approval: You provide feedback, and the factory refines the prototype. This may involve several iterations.

- Pilot Production Run: A small initial batch is produced to test the mass production process.

- Mass Production & Quality Control: Full-scale production begins, with rigorous QC checks at every stage.

| OEM Pros | OEM Cons |

|---|---|

| Total Brand Control: Your product is 100% unique and perfectly reflects your brand identity. | Extremely High Upfront Costs: Mold and tooling costs can range from 5,000to5,000 to 50,000+ per faucet. |

| Full IP Ownership: You own the design, giving you a powerful competitive advantage and asset. | Very Long Time-to-Market: The entire process from concept to shelf can take over a year. |

| Higher Potential Margins: A unique product can often command a premium price in the market. | Requires Significant Technical Expertise: You need in-house or contracted design and engineering talent. |

| No Competition on the Same Design: No other brand will have your exact product. | High Risk: If the product fails in the market, you have lost a substantial investment in R&D and tooling. |

Who is the OEM model for?

- Established Global Brands (e.g., Kohler, Delta) who need to protect their brand identity and innovation pipeline.

- High-End Niche & Boutique Brands whose entire value proposition is based on exclusive, unique design.

- Companies with Strong In-House R&D and a clear, innovative product vision.

A Deep Dive into the ODM Process: The Path to Speed and Efficiency

The ODM model is the great enabler of the modern faucet market, allowing brands of all sizes to compete.

The Step-by-Step ODM Faucet Development Process:

- Manufacturer Catalog Review: The manufacturer presents you with their catalog of pre-designed faucet models.

- Model Selection: You choose the base model that best fits your brand’s aesthetic and target price point.

- Customization Specification: You define the desired modifications:

- Surface Finish: Brushed Nickel, Matte Black, PVD Brushed Gold, etc.

- Handle Design: Choose from a library of compatible handle options.

- Branding: Your logo is laser-etched or stamped onto the product.

- Components: Specify a particular cartridge or aerator brand.

- Packaging: Design custom packaging with your branding.

- Sampling & Approval: The factory produces a sample with your customizations for your approval.

- Mass Production & Quality Control: Once approved, mass production begins.

| ODM Pros | ODM Cons |

|---|---|

| Extremely Fast Time-to-Market: You can go from concept to having a product ready to ship in as little as 60-90 days. | Product is Not Unique: Your competitors can (and likely will) source a very similar product from the same factory. |

| Very Low Upfront Costs: No R&D, engineering, or mold costs. You only pay for the product and any minor customization fees. | No IP Ownership: The design belongs to the factory. You are essentially “renting” it. |

| Lower Risk: You are choosing a product that is already designed, engineered, and often tested, reducing the risk of failure. | Limited Customization: You can only change certain elements; the core design and dimensions are fixed. |

| Leverages Manufacturer Expertise: You benefit from the manufacturer’s R&D and market knowledge without having to pay for it directly. | Dependent on Manufacturer’s Design Pipeline: Your brand’s innovation is tied to the manufacturer’s ability to create new designs. |

Who is the ODM model for?

- Startups and New Brands who need to get to market quickly with minimal capital investment.

- Large Retailers & Big-Box Stores who need to source a wide range of products for their private label brands.

- Project-Based Businesses (e.g., hotel suppliers, builders) who need reliable, certified products without needing them to be unique.

- Brands Competing on Price & Distribution rather than unique design.

Expert Tip: Even in an ODM model, push the boundaries of customization. Ask your supplier about combining elements from different models. Can you use the spout from model A with the handle from model B? A flexible ODM partner will often be willing to create these “hybrid” products for you.

Frequently Asked Questions (FAQ): Making the Right Choice

Q1: How much does a typical faucet mold cost in an OEM project? This varies widely based on complexity, but as a general guide for a faucet body mold:

- Simple Zinc Alloy Faucet: 3,000−3,000 – 8,000

- Standard Brass Faucet: 8,000−8,000 – 20,000

- Complex, Multi-Part Brass or Stainless Steel Faucet: 20,000−20,000 – 50,000+ This cost does not include separate molds for handles or other components.

Q2: In an OEM model, how do I protect my design and intellectual property when working with a Chinese manufacturer? This is a critical concern. Do not rely on your home country’s patents alone.

- File for a Design Patent in China: This is the most effective protection. It’s relatively inexpensive and gives you legal standing in China.

- Sign a Comprehensive NNN Agreement: Before sharing any sensitive information, have the factory sign an NNN (Non-Disclosure, Non-Use, Non-Circumvention) agreement. Unlike a Western NDA, an NNN is specifically designed for China and is enforceable in Chinese courts. It must be written in Chinese and governed by Chinese law.

- Work with Reputable Manufacturers: Established factories with a long history of working with international brands have a reputation to protect and are far less likely to steal a design.

Q3: Can I start with an ODM product and later move to an OEM product with the same supplier? Absolutely! This is a very smart growth strategy. You can use an ODM product to test the market, establish your sales channels, and generate cash flow with low risk. As your brand grows and you have more capital, you can then invest that revenue into developing a unique OEM product with the same trusted manufacturing partner.

Conclusion: A Strategic Decision for Your Brand’s Future

The choice between OEM and ODM is not a question of which is “better,” but which is right for your business at its current stage.

- Choose ODM if your priorities are speed, efficiency, and minimizing financial risk. It’s the perfect launchpad for new brands and the workhorse for large-scale retailers.

- Choose OEM if your core strategy is built on unique design, brand identity, and long-term competitive advantage. It’s the path for innovators and established market leaders.

Reflect on the history of the industry: even the biggest manufacturers started by learning from others before they began to innovate. Your brand can follow the same path. By understanding the strategic implications of both models, you can make an informed decision that aligns with your resources, protects your interests, and sets your faucet brand on a clear path to success.

Recommended Links

Internal Links:

- Top 10 Faucet Manufacturers in China (2025 Buyer’s Guide)

- Why SUS304 Stainless Steel Faucets Are the Smarter Choice

External Links (Authoritative Sources):

- World Intellectual Property Organization (WIPO): Protecting Your IP – An essential resource for understanding international IP protection.

- Wikipedia: Original Equipment Manufacturer (OEM) – For a broad, academic definition of the term.

- Thomasnet: What’s the Difference Between an OEM and an ODM? – A reputable industrial sourcing platform’s take on the subject.